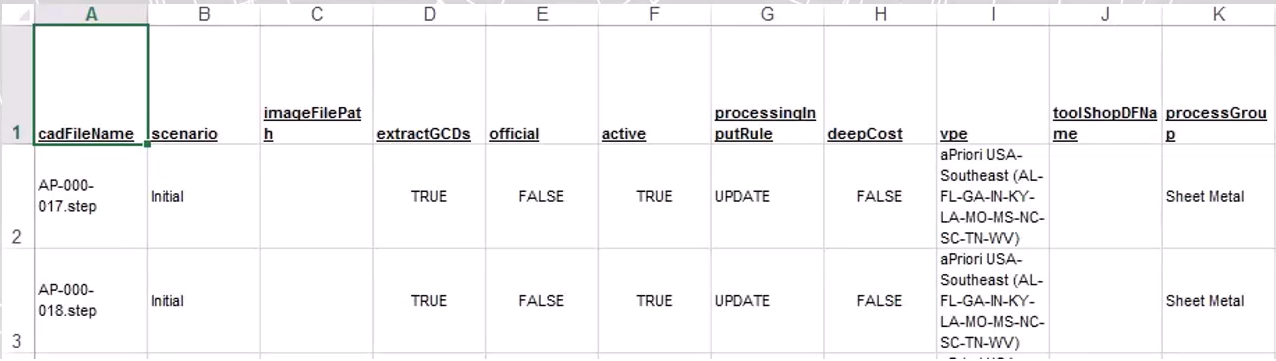

You can supply data to bulk costing using an Input User Sheet - a spreadsheet, containing parts, production information, overrides for CSL values, and other cost inputs.

Input user sheets provide a quick way to provide large sets of information into the bulk costing process, avoiding duplication of this information. You can also set up advanced functionality with Input User Sheets. For example, you can link to UDAs and set Process Setup Options (PSO), such as number of cavities for injection molding. See Process Setup Option columns.

When to use Spreadsheets

Input User Sheets require setup and maintenance, so you should decide whether this is worthwhile for your organization.

For example, if your organization has a large library of parts (hundreds or thousands), with your production parameters changing significantly for different process groups, then using Input User Sheets is worthwhile.

Similarly, if you wish to use advanced features such as Excel macros, again Input User Sheets are worth considering.

Note: Spreasheet values override values from other sources. See Precedence of production input overrides.

Create an Inputs File

-

Create a new bulk cost group and edit values in the Bulk Costing & Analysis UI. See Bulk Costing Using the UI.

-

Select File > Export User Inputs Spreadsheet to save a user inputs file in Excel spreadsheet format, with the columns in the spreadsheet files mapping to the columns in the Bulk Costing & Analysis UI.

Edit User Inputs File

You can now edit this information in the spreadsheet created - see the following sections for details.

Supplying Data to Bulk Costing

After editing the spreadsheet data, you can use this file as input during your bulk costing process - see Bulk Costing Using the UI